A LONG HISTORY

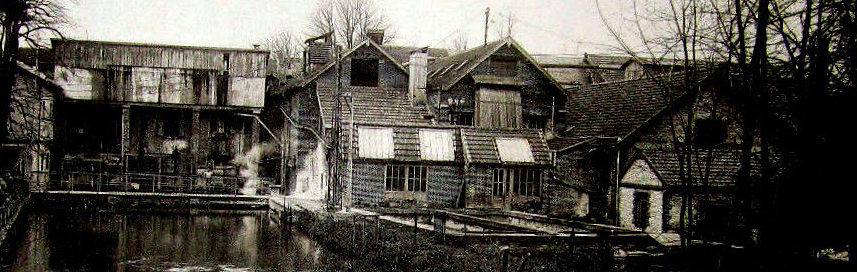

Even before the creation of LA CHANVRIÈRE, the producers in Aube were already supplying their hemp to a paper pulp mill (SA des papeteries BOLLORÉ) located in Troyes. The end of the straw supply contracts was the triggering factor for the construction of a defibration unit. In 1973, LA CHANVRIÈRE registered its statutes, and its transformation facility was established in Bar-sur-Aube.

AN OPTIMIZED FACILITY

Since then, our Bar-sur-Aube factory has undergone continuous modernization, benefiting from both advancements in available machinery and, most importantly, the expertise of our employees who have optimized its efficiency. In 2020, La Chanvrière relocated to St Lyé, thereby doubling its production capacity.

To this day, our unit defibers straw at full capacity, using the utmost care to ensure that the straw harvested by our producers meets their contractual commitments:

- Color,

- Moisture content,

- Health condition,

- Absence of plastic (the straw bales are tied with natural fiber twine).

This process allows us to produce the highest quality fibers (fineness, length, chènevotte content) to meet the specifications of our paper mill clients.

RECOGNIZED QUALITY, CONSISTENCY OF DELIVERIES, LONG-TERM SUPPLY CAPACITY

Quality control of the incoming straw, yield monitoring, and fiber quality control are essential elements of the guarantees required by our clients:

- Metal detection

- Foreign body control

- Fiber color measurement

- Homogeneity measurement

- Moisture content control

- Residual chènevotte content control

- QR Code coding for traceability

- Fiber lot classification

Thus, LA CHANVRIÈRE has become the leading company in the field of paper fibers. Our clients, both European and global, unanimously recognize the consistency and quality of our fibers, as well as our ability to honor contracts.