A PIONEER BECOME A REFERENCE

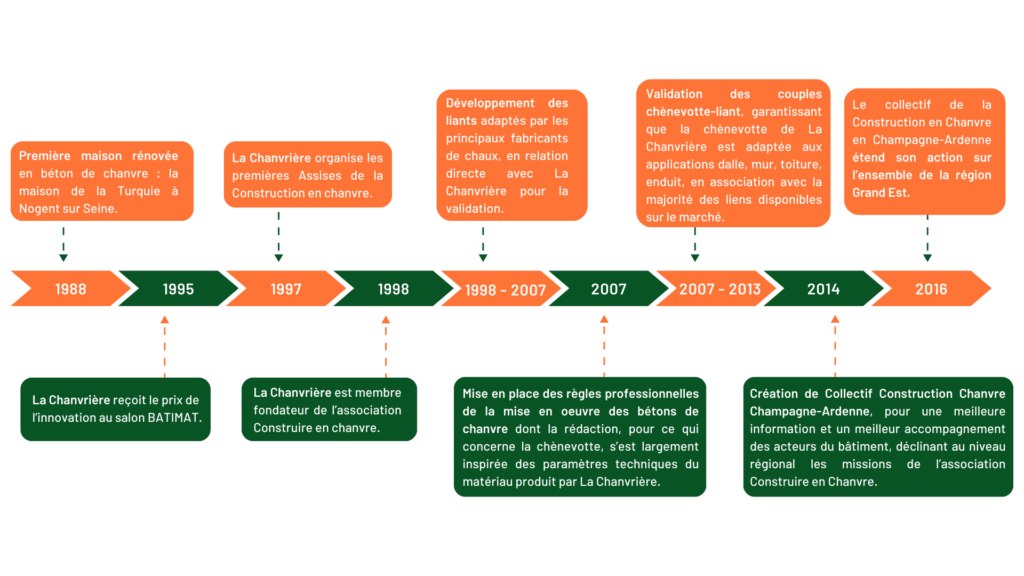

Naturally, hemp is known and recognized for its use in construction, but few people know that hemp mortar originated in the Aube region in the late 1980s. A bit of history:

RECOGNIZED PRODUCTS

Already a supplier to the major lime producers who wanted to sell hemp in addition to their lime, LA CHANVRIÈRE decided in 2010 to market hemp aggregate under its own brand KANABAT. Validated with most lime-based binders in line with the performance requirements of the Professional Rules for the Application of Hemp Concrete, KANABAT carries the GRANULAT CHANVRE BÂTIMENT label, which guarantees its compliance with the label’s specifications:

- Light color

- Controlled granulometry

- Reduced dust content

- Optimal moisture content

- Constant apparent density

Continuous internal and external control ensures the product’s authenticity. The application of hemp concrete or mortar with KANABAT must be done according to the recommendations of the binder manufacturers.

The application varies depending on the lime used and the specific application (wall, slab, roof, plaster). KANABAT can be used for hemp concrete applied manually (formwork) or by machine spraying: the size of the aggregates is adapted for these two application methods. Using KANABAT (or any other raw chènevotte) in dry form, poured between partitions or beams, is not recommended (www.construire-en-chanvre.fr).

HEMP FIBERS: AN ALTERNATIVE WAY TO INSULATE

Alongside the development of chènevotte in hemp mortars and concretes, LA CHANVRIÈRE is the originator of the production of insulation materials made from its fibers, attracting the leading manufacturers at the time.

To meet this market demand, the producers of LA CHANVRIÈRE adapted their farming methods to produce hemp straw specifically tailored for defibration.

The transformation plant in Saint Lyé has equipped itself with a refining line so that these fibers can meet the specifications of their clients: color, length, fineness, moisture content, impurity levels—criteria that are continuously quality-checked.

Used by several European manufacturers, the fibers from LA CHANVRIÈRE are now incorporated into several types of insulation products, either in rolls or semi-rigid panels.

They are also used in felts for acoustic insulation underfloor layers. Most of LA CHANVRIÈRE‘s clients are on annual contracts that guarantee a consistent supply of high-quality material throughout the year, based on their needs.